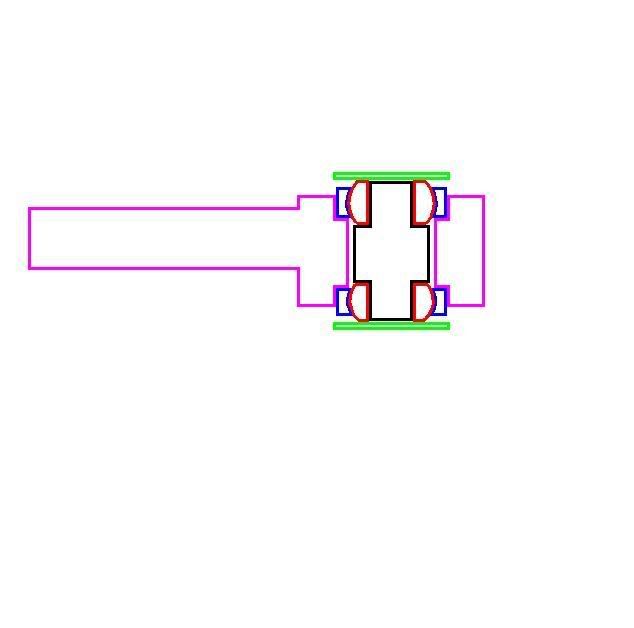

This is how I machine the spherical bearing mod.

Purple is the arm

Blue is the bearing race/body

Red is the bearing

Black is the inner sleeve

Green is the I.A.Brace

You should be able to see how you can tighten this as much as you like and the arm and bearing race will turn freely while the brace, sleeve, and bearing will be completely solid mounted to your frame. You can also see the only place where any slop can be a factor is from the bearing/race fit. These bearings are rated at 35k lbs each and should wear for the life of your truck if kept lubricated.

I would like to note that the fit between the bearing and the race does give a small amount of wiggle in this application.